视觉检测

芯片生产高质量管控的检测工具

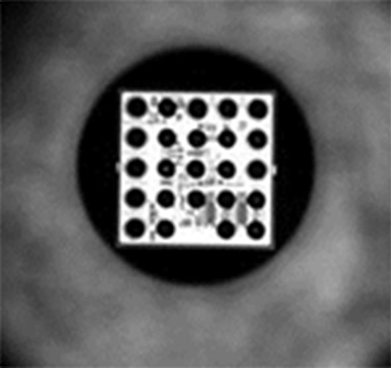

半导体工业质量标准要求高速100%视觉检测工艺流程。尤其是晶圆级封装后道更要保证0缺陷产出。纽豹提供的高精度视觉检测系统可以实现最高质量产出。

新型:纽豹侧边检测

纽豹独有的侧边检测系统命名为SIDEWALL。由此芯片的四个侧边都可以被检测,日净产出效率创出新高。纽豹的DS15000,DS20000及多功能芯片分选系统DS Variation都配备SIDEWALL检测系统。缺陷最小可检测尺寸为10µm。可根据客户需求对已经安装的DS15000进行现场升级。

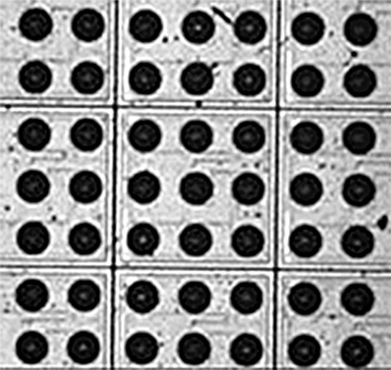

晶圆检测

(晶圆正面检测)

- 晶圆对齐

- 芯片确认

- 芯片正面检测

- 切割线检测

芯片运行中检测

- 芯片确认

- 芯片检测

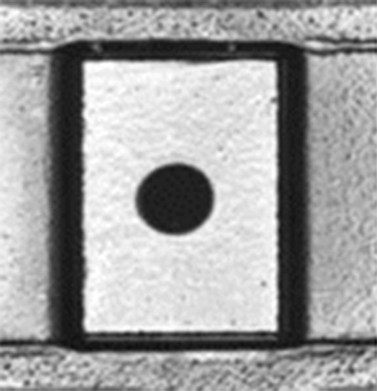

芯片放置前检测

(口袋位置检测)

- 位置检测(芯片放置前)

- 芯片在口袋中位置确认

- 芯片背面检测

Inspection tools for highest quality control in chip production

The quality standards of the semiconductor industry require a high precision 100% inspection in fast running processes. Especially the backend processes in the WLCSP production are more and more subject to this zero defect policy. Mühlbauer offers a wide range of vision inspection features to deliver highest quality output.

Mühlbauer SIDEWALL Inspection

Mühlbauer is pleased to announce the launch of a worldwide unique visual inspection feature called SIDEWALL inspection. Thereby all four side walls of a chip are inspected leading to an unprecedented degree in daily net output. The new side wall inspection is available for Mühlbauer’s die sorting systems DS 15000 and DS 20000 as well as DS Variation. Defects down to 10µm can be recognized. Field upgrades for existing DS 15000 systems can be quoted upon request as well.