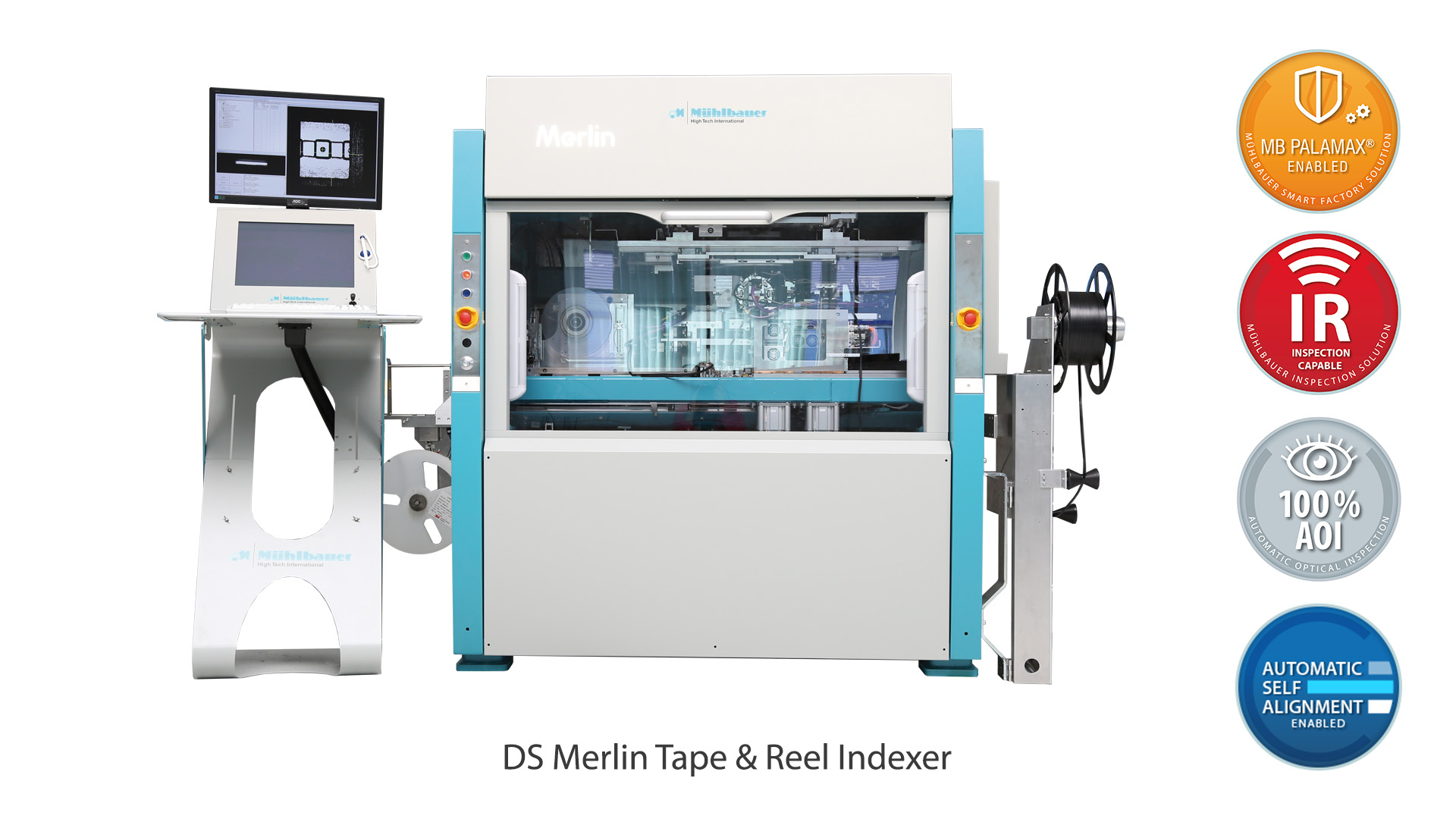

DS Merlin

MÜHLBAUER'S HIGH-SPEED DIE SORTING MACHINE

DS MERLIN is a high-speed die sorting machine suitable for various applications such as Tape and Reel or Wafer/Panel. It can handle dies (chips) that are either flip chip or non-flip. Mühlbauer has developed the next step in high-speed die sorting - the DS Merlin 60000 with a record throughput of up to 55,000 UPH including full 6-side inspection. The machine features the patented pick and place system that combines two rotary wheels with a fully automatic self-alignment system. In addition to Tape & Reel application, DS MERLIN supports Wafer/Panel application and can achieve throughput of up to 30,000 UPH.

The Vision inspection system has been modernised to the latest standards, with a minimum resolution of 4MP and the highest quality for visible and IR defect detection with a detection capability down to 5-10 μm. It is now also capable of using different IR wavelengths as well as Laser Groove IR inspection. DS MERLIN has been extensively tested and has earned the customer’s trust with over 450 machines installed worldwide. The DS MERLIN can be optionally equipped with our MB PALAMAX® for equipment smartification and our ARC to eliminate downtime due to carrier tape changes. These additions greatly reduce the operator's need and maximize tool efficiency.

KEY FEATURES:

-

Flip or Non-flip capability

-

Lower cost of ownership with patented wheel(s) rotary system

-

Automatic self-alignment with super-fast change over guarantee

-

Integrated full 6-side AOI inspection

Infrared inspection: sidewall, backside, post place and laser groove inspection down to 5µm with minimal impact on throughput

-

Automatic reel changer available

BENEFITS:

- Ultra small die handling capability (0.2 x 0.4 mm)

-

Full speed and 100% 6-side AOI inspection without influencing the speed+ IR capability

- Placement accuracy ±30μm

- De-taping (Tape to Tape) capability

- 100% traceability with MB PALAMAX (industry 4.0 enabled)

TROUGHPUT:

Tape and Reel

-

Flip : Up to 55,000 dies/hour

-

Non-flip: Up to 30,000 dies/hour

Wafer/Panel

-

Flip: Up to 30,000 dies/hour

-

Non-flip: Up to 30,000 dies/hour