Produktion und Prüfung von RFID-Inlays

Mühlbauer RFID-Inlay-Systeme decken alle gängigen ePassport- und Smart Card-Applikationen ab, egal ob es sich um das ID-1- oder ID-3-Format handelt und unabhängig davon, ob es sich um Hybridkarten, Dual Interface Karten oder kontaktlose Karten handelt.

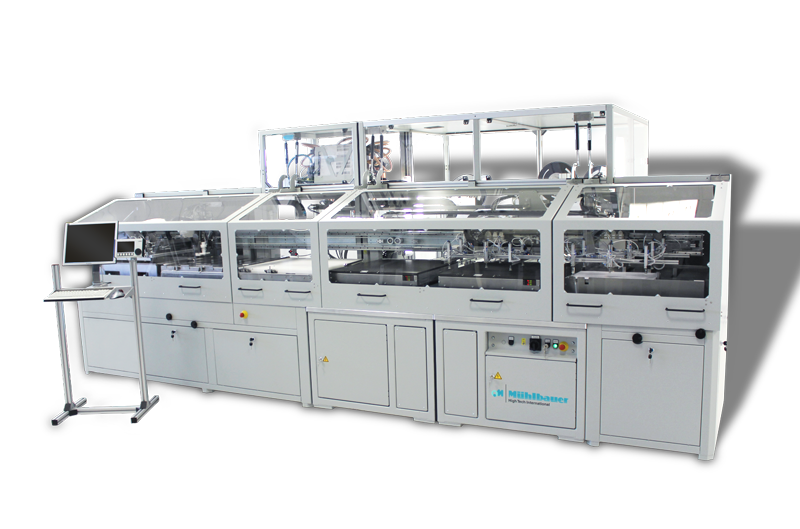

Für das Einbetten von Drähten und die Produktion von RFID-Inlays bietet Mühlbauer mit seiner MTT-Serie eine echte All-in-One-Lösung. Alle Prozesse befinden sich in einem modularen System: Chipmodul-Stanzen, Chipmodul-Implantieren, Ultraschall-Draht-Einbetten, Thermokompressions-Chip-Schweißen sowie Testen inklusive Bad-Unit-Markierung.

Der Prozessschritt RFID-Inlay-Prüfung ist für die Qualitätssicherung von großer Bedeutung. Dabei werden die integrierten Transponder in den vorlaminierten, kollationierten, laminierten oder inlayierten RFID-Bögen getestet, um die Funktionsfähigkeit der gesamten Ausgabe zu gewährleisten.

Mühlbauers RFID Inlay Produktions- und Testsysteme

MTT 2462

- All-in-One-Lösung für die Produktion von Wire Embedding & RFID-Inlays

- Know-How wird komplett im Haus gehalten

- Einfacher Import von CAD-Daten

- Beliebige Antennengeometrien sind möglich, auch Mäander

- Leistungsstarke Design-Software

- Hohe Stabilität mit Vakuum statt Klebstoff

- Elektrisch-optische Prüfung inkl. Schlechtteilmarkierung

- Reklamierte Bleche können einfach nachbearbeitet werden

- MB INCAPE geeignet

ITH 540 & IT 50

- Durchführung von Tests & Vorpersonalisierung

- Hohe Flexibilität hinsichtlich Materialien & Sheet-layouts

- Bedienerfreundlich

- Automatische Ausschussmarkierung

- Automatische Zählung von funktionierenden & verworfenen Antennen

- Bis zu 1.000 Bögen pro Stunde

- IT 50: Manuelles Inlay-Prüfgerät

- Test basiert auf ATS (Answer To Select) Test der Antennen

- Konfiguration ist einstellbar auf Kundenanforderungen nach ISO 14443A oder ISO 14443B

ITH 550

- Durchführung von Tests & Vorpersonalisierung

- Hohe Flexibilität bezüglich Materialien & Bogenlayouts

- Bedienerfreundlich

- Automatische Ausschussmarkierung

- Automatisches Zählen von funktionierenden & verworfenen Antennen

- Bis zu 10.000 Bögen pro Stunde

IAL 10000

- Roll-to-Sheet, Sheet-to-Sheet, Roll-to-Roll

- Vollständige Inlay-Montage (einschließlich Karten- / E-Halter-Seitenlagen-Zusammenstellung)

- Absolut modular, wie es der Prozess erfordert

- Großes Format: 750 x 750 mm

- Automatische Winkel X, Y-Einstellung durch Vision-System an verschiedenen Maschinenstationen

- Inlay-Qualitätssicherung: Vision-Inspektion und/oder elektrischer Test (ATS oder RFM), Bad-Mark-Drucker, Reject-Tray