RFID Inlay Production and Testing

Mühlbauer RFID inlay systems cover all common ePassport and smart card applications, regardless of whether they are in ID-1 or ID-3 format and independently of whether they are hybrid cards, dual interface cards or contactless cards.

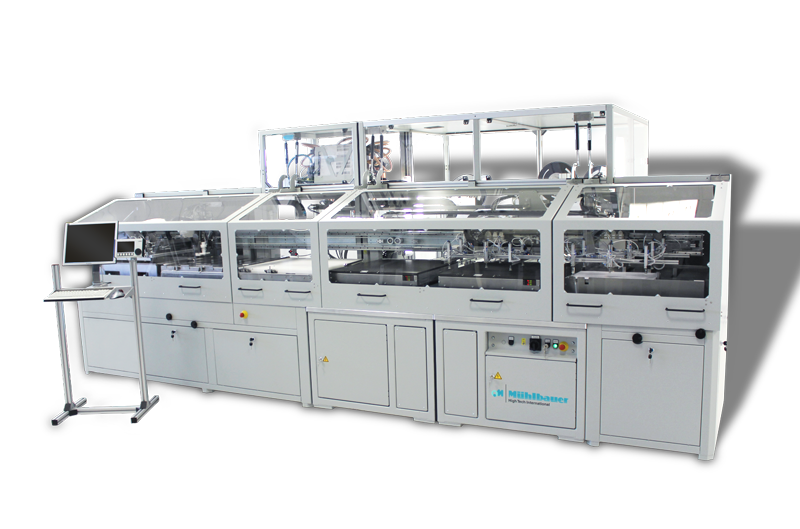

Mühlbauer offers a true all-in-one solution for wire embedding and RFID inlay production with its MTT series. All processes are located in one modular system: chip module punching, chip module implanting, ultrasonic wire embedding, thermo-compression chip welding as well as testing including bad unit marking.

The RFID inlay testing process step is of great importance for quality assurance. This involves testing the integrated transponders in the pre-laminated, collated, laminated or inlaid RFID sheets to ensure the functionality of the entire output.

Mühlbauer's RFID Inlay Production and Testing Systems

RFID Inlay Production System MTT

- All-in-one solution for wire embedding & RFID inlay production

- Know-How is completely kept in-house

- Easy import of CAD data

- Any antenna geometry is possible, including meander

- Powerful design software

- High stability with vacuum instead of adhesive

- Electrical optical testing incl. bad unit marking

- Rejected sheets can easily be reworked

- MB INCAPE ready

ITH 540 & IT 50

- Realization of testing & pre-personalization

- High flexibility regarding materials & sheet layouts

- Operator-friendly

- Automatic reject marking

- Automatic counting of functional & rejected antennas

- Up to 1,000 sheets per hour

- IT 50: Manual inlay testing device

- Test based on ATS (Answer To Select) test of antennas

- Configuration is adjustable to customer requirements according to ISO 14443A or ISO 14443B

ITH 550

- Realization of testing & pre-personalization

- High flexibility regarding materials & sheet layouts

- Operator-friendly

- Automatic reject marking

- Automatic counting of functional & rejected antennas

- Up to 10,000 sheets per hour

IAL 10000

- Roll-to-Sheet, Sheet-to-Sheet, Roll-to-Roll

- Complete inlay assembly (including card / e-holder page layer collating)

- Fully modular as the process requests

- Wide format: 750 x 750 mm

- Automatic angle X, Y adjustment by vision system on various machine stations

- Inlay quality assurance: vision inspection and/or electrical test (ATS or RFM), bad mark printer, reject tray