MB ALFRESCO 图像

The photo on the personalized identity card is the main visual identifier of the document’s holder. It is of utmost importance to present this main identifier in a perfect quality as well as to apply suitable protection against counterfeit attempts to change or manipulate the photograph. Moreover a main influence factor of the document specification is the service lifetime for the complete identity document as well as the photo.

The launch of the grayscale laser engraving technology on polycarbonate documents marked a breakthrough for the personalization of identity documents. During this process the holder’s portrait is laser engraved inside the multi-layered polycarbonate document structure and thereby protected against any kind of manipulation or substitution. Furthermore the latest laser engraving process allows the engraving of the high-resolution photos while keeping all the original photo details, ensuring a perfect authentication accompanied by a high level of security and durability. This technology is the first choice in different forensic committees around the world with regard to these characteristics.

An identity project, however, must not only fulfill highest standards of security and durability but also needs to gain the acceptance of the general public. Authorities are faced with the general opinion that the implementation of grayscale images means taking a step backwards in technology. Because of that reason Mühlbauer has extended its portfolio with the Mühlbauer COLOR FAMILY containing MB D2T2 Picture, MB ALFRESCO PICTURE and MB EMBEDDED PICTURE. These different technologies are designed to meet the various demands with regard to quality, cost efficiency and durability.

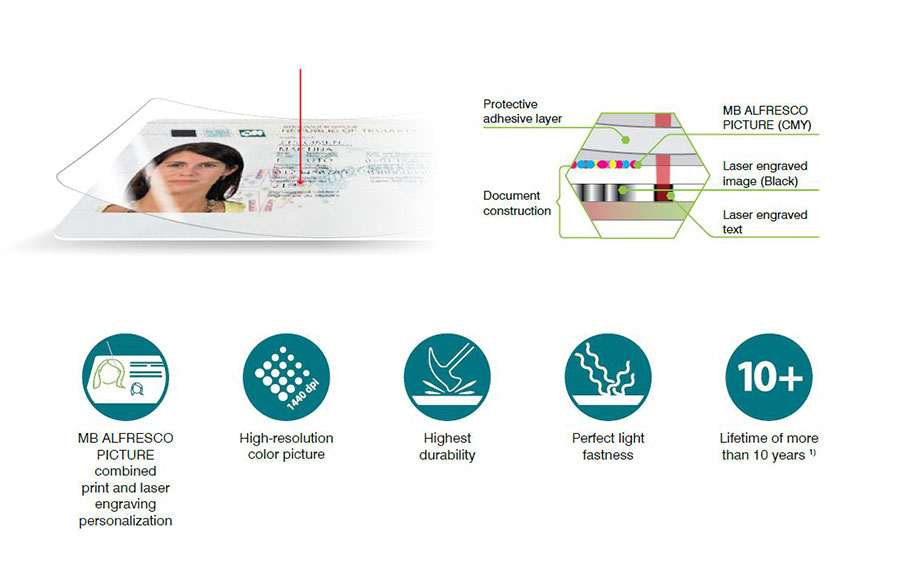

Facts & Figures

| Applications | High Secure Cards, Identity Cards, Driver's Licence, Polycarbonate Passport Datapages |

| Durability |

10 + years 1) Depending on normal use conditions and used protective layer |

| Resolution | Up to 1440 dpi |

| Document Material | PC, PVC, other materials on request |

| Consumables | MB ALFRESCO INS, protective Layer |

| Central Security Aspect | Personalization on different layers of document |

| Personalization Infrastructure | Centralized and decentralized |

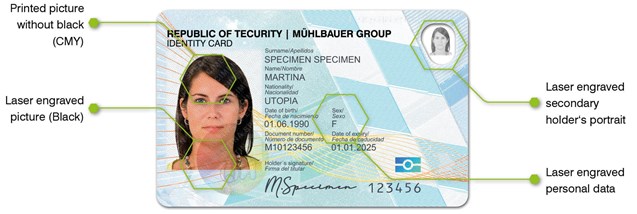

The sophisticated MB ALFRESCO PICTURE technology smartly combines color picture personalization with laser engraving. To achieve the high-secure personalization result, the image of the holder is split into two parts using special image processing algorithms. The converting process transfers all picture information, which describe the details (forensic information), into a greyscale image. This greyscale information containing all contrast information of the picture is engraved into the inner layers of the document by using laser engraving technology. The remaining color parts are converted to a separate color image, which is then printed on the blank document’s surface. Due to the special characteristics of the ink, the colors penetrate the card surface, thus thwarting counterfeiting attempts of scratching off the surface. The final result is a high resolution color picture, which shows utmost details. This picture technology has the same long lasting durability characteristics and resolution as a pure laser engraved picture. Since the color part of the photo is printed on the document surface, however, it has to be additionally protected by an adhesive layer due to durability reasons. Attempts to remove the photo are useless as the greyscale information remains inside the document. The greyscale picture can be additionally verified under IR light. Due to the special color properties of the MB ALFRESCO PICTURE, optical variable features (e.g. Holograms) shine through the color picture and protect it thereby against replication by photo copying. The highest level of security is reached by laser engraving the biographical data and a secondary holder’s portrait into the document material. The technology is suitable for a decentralized as well as a centralized personalization concept.

MB ALFRESCO PICTURE

MB ALFRESCO PICTURE