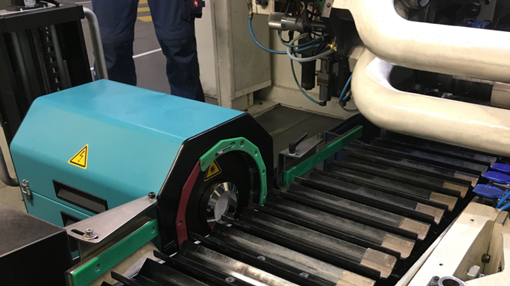

TEMA CTI-CONVEYOR

TEMA CTI-CONVEYOR for can and bottle head inspection is Mühlbauer’s proven system solution which has especially been designed for flange and shoulder inspection at the output conveyor. The cans are continuously delivered to the inspection unit in half-shells; flange and shoulder are projecting the rim. The camera is triggered by a sensor system to ensure that the image is recorded exactly when the can is best positioned in front of the camera lens. TEMA CTI-CONVEYOR spots defects like cracks, split curls, burrs, dents, deformation, stains, and pollution on the flange; furthermore shoulder defects like stains, pollution, dents, deformation, cracks, coating defects, and even print defects. TEMA CTI-CONVEYOR communicates with the PLC and gives a defect signal every time a defective can/bottle has to be rejected.

TEMA CTI-CONVEYOR performance data:

- Suitable for diameter up to 66 mm (other dimensions on request)

- Throughput 300 parts/min

TEMA CTI-CONVEYOR is:

- Proven and tested – numerous installations worldwide

- Flexible –suitable for every can making line

- Easy to use – automatic functions and operator support

- Precise – detection of smallest defects even on problematic surfaces

- Durable – high-end hardware

- Reliable – high availability and low maintenance costs

TEMA CTI-CONVEYOR provides:

- 100% objective inspection - zero defect concept

- Support through global service network

- Best adaptation to each can/bottle design

- User friendly defect indication in the live image

- Inspection and process data for further processing

- Additional features – TEMA STATISTICS GRAPH