for tubes/cans/cups

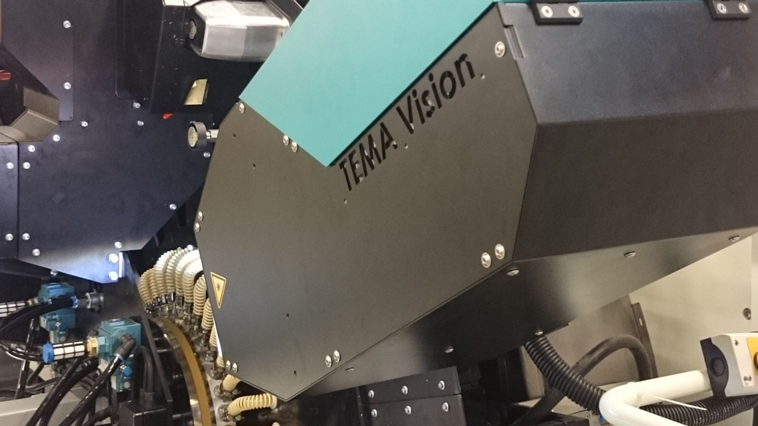

Mühlbauer’s TEMA Vision print inspection systems for tubes, cans, cups, and other tubular bodies have been designed to be integrated into the printing machine. They provide inspection capabilities for all printing methods, inks, and coatings incl. high gloss and brushed cans. Initially developed for demanding applications from the pharmaceutical industry these vision systems are capable of suiting highest requirements.

Print Inspection for highest demands

TEMA PI-CUP square

- High accuracy print inspection on square cups (both long and short sides)

- Inline integrated into a cup printer on two wheels

- High-speed inspection, 800 cup sides/min

- Suitable for different materials, inks, and coatings

- Inspection with two different reference images

- Individual parameters for each inspection zone

- Automatic adjustments and parameter pre-views

- High-end camera and computer hardware

- Live images/defect image storing

- Protocol, statistics

TEMA PI-CYLINDER

- High accuracy print inspection on tubes, cans, and other tubular bodies incl. barcode verification

- Inline integrated into the printing machine

- Customizable for a variety of decoration lines

- Suitable for all print techniques, materials, inks, and coatings

- Individual parameters for each inspection zone

- Automatic adjustments and parameter pre-views

- High-end camera and computer hardware

- Live images/defect image storing

- Protocol, statistics

TEMA PI-CUP

- High accuracy print inspection on cups incl. barcode verification

- Inline integrated into a cup printer

- High-speed inspection, 600 cups/min

- Suitable for different materials, inks, and coatings

- Individual parameters for each inspection zone

- Automatic adjustments and parameter pre-views

- High-end camera and computer hardware

- Live images/defect image storing

- Protocol, statistics