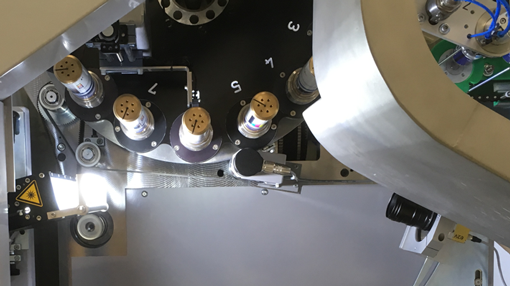

TEMA SI-CYLINDER

TEMA SI-CYLINDER is Mühlbauer’s solution for surface inspection on tubes, cans, cartridges, etc. in a printing unit or base coat station and can be installed in almost every type of machine. The inspection is executed prior to the printing process on a free, driven mandrel. While being rotated the tube/can is completely scanned. TEMA SI-CYLINDER detects optical defects like stains, spots, coating defects, pollution, etc. and mechanical defects like deformation, holes, scratches, dents, etc. When the scan of the surface is complete and the quality assessment is available the inspection system provides a signal to the machine control which, in case of a defect detected, can be used by the PLC for initiating a warning signal, a reject of the tube/can or a machine stop if necessary.

TEMA SI-CYLINDER performance data:

- Suitable for length up to 260 mm

- Suitable for diameter up to 90 mm

- Throughput approx. 300 parts/min

TEMA SI-CYLINDER is:

- Compatible – can be combined with TEMA PI-CYLINDER print inspection

- Flexible – different installation/hardware options

- Easy to use – automatic functions and operator support

- Precise – excellent inspection performance

- Durable – high-end hardware

- Reliable – high availability and low maintenance costs

- Versatile – suitable for various base coats and natural aluminum

TEMA SI-CYLINDER provides:

- 100% objective inspection - zero defect concept

- Support through global service network

- Best adaptation to each surface characteristic

- User friendly defect indication in the live image

- Inspection and process data for further processing

- Additional features – TEMA STATISTICS GRAPH