CIM-12

Fully automatic final inspection for aerosol cans & aluminum bottles

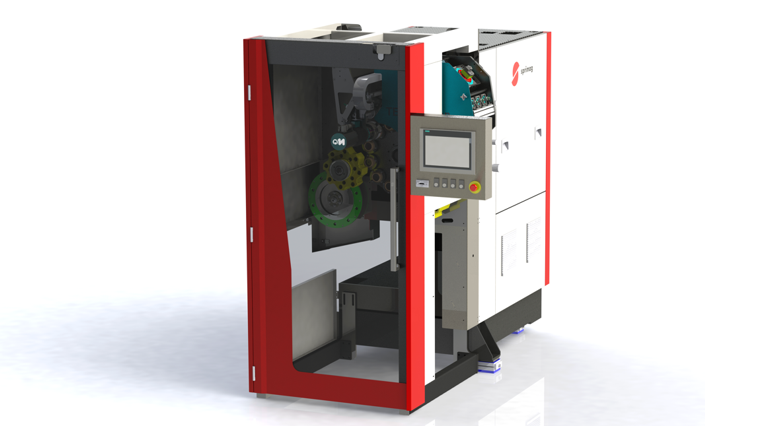

TEMA CIM-12 is the complete solution for a fully automatic final inspection of monobloc aerosol cans or aluminum bottles at the output conveyor of the necking machine (or alternatively behind the post washer). Integrated into the high-performance can handler produced by the company Sprimag up to four inspection units warrant the flawless quality of the can/bottle prior to packaging and enable a completely automated production line incl. packaging.

Fully equipped the CIM-12 operates with:

- TEMA CTI for inspection of curl and shoulder/neck of the can/bottle

- TEMA SPI-CYLINDER for print inspection and surface inspection of the lateral surface incl. thread, side area of the curl, side area of the shoulder as well as the transition area in between

- TEMA SHAPE CONTROL for 3D measurement of the can/bottle body

- NEW: TEMA PINHOLE DETECT for optical detection of micro-holes (pinholes).

The finished can/bottle is comprehensively tested through different inspection methods. The resulting redundancy increases the inspection reliability and reduces the risk of pseudo-rejects since each inspection unit works within its best parameter range. The can handler picks up the cans/bottles from the output conveyor of the necking machine and takes them to each inspection unit. For print inspection, 3D measurement, and pinhole detection the can/bottle is rotated. After the can/bottle has passed all inspection units the can handler takes it back to the conveyor.

Defective products are ejected.

CIM-12 can be equipped with separate input conveyors and output conveyors to compensate different machine heights if required.

CIM-12 performance data

- Suitable for can/bottle diameter up to 66 mm

- Maximum print height: 250 mm

- Maximum scan area for 3D: 270 mm

- Detectable pinholes: holes >10 µm

- Maximum throughput: 200 parts/min.

CIM-12 is:

- Unique – no comparable inspection solution available

- Compact – easy integration into every production line

- Comprehensive – checks all relevant quality characteristics of the can/bottle: appearance, functionality, tightness

- Dependable – uses 2D and 3D techniques as well as photomultiplier for a reliable defect detection

- Precise – detects even smallest defects in hard-to-see areas

- Durable – high-end handling and inspection hardware

- Easy to use – wizard, auto-functions and operator support

CIM-12 provides:

- 100% objective inspection – zero-defect-concept

- Uniform operating concept for all inspection methods

- Defect indication in the image, dimensional deviations given in numbers

- 3D views

- Inspection data and process data for further processing

- Highest competence in handling and vision

- Support through global service network