for can/bottle tops

Mühlbauer’s Vision solutions for inspecting the head of aerosol cans and aluminum bottles can be either integrated into the necker or used at the output conveyor. The inspection focusses on two different areas: the flange and the shoulder. The neck, as a third area, is additionally considered for bottles. Objective of the inspection is to ensure the functional integrity as well as the immaculate look of the can/bottle for a gas-tight, appealing final product.

Assurance of fuctional and optical quality of aerosol cans and aluminum bottles

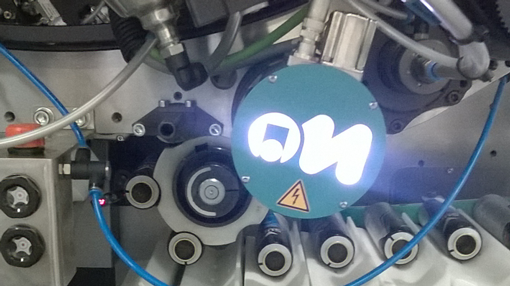

TEMA CTI-NECKER backside

- Inline integrated into a necking machine

- Suitable for all common shoulder geometries

- High precision surface inspection of the flange (top, side, backside)

- High precision inspection of shoulder (including print inspection, if required)

- Additional modules for neck inspection of aluminum bottles

- Easy set-up of new product types

- High-end camera and computer hardware

- Live images/defect image storing/protocol/statistics

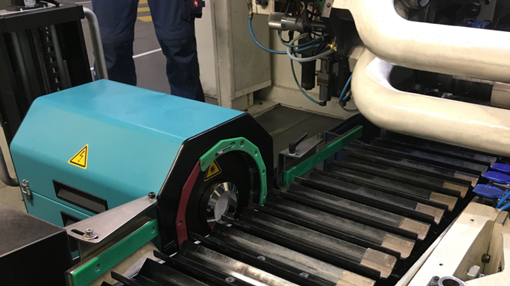

TEMA CTI-CONVEYOR

- Integrated at the output conveyor

- Suitable for all common shoulder geometries

- High precision surface inspection of the flange

- High precision inspection of shoulder (including print inspection, if required)

- Easy set-up of new product types

- High-end camera and computer hardware

- Live images/defect image storing/protocol/statistics