TEMA ISI-CUP

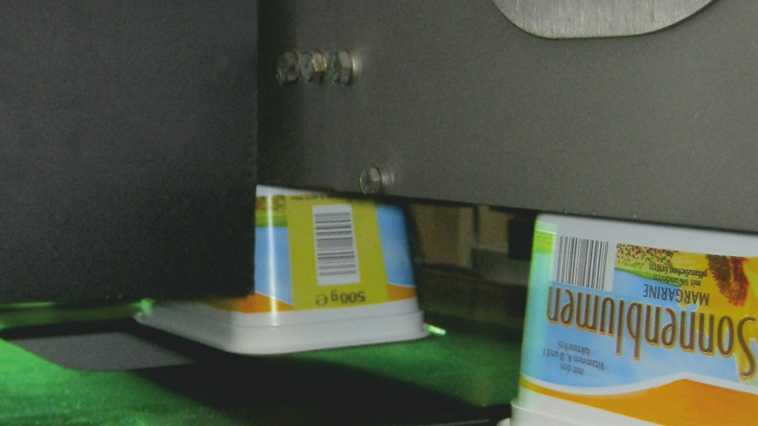

TEMA ISI-CUP, Mühlbauers Lösung für die Kontrolle der Innenoberfläche von Bechern, wird üblicherweise zusammen mit einem Vakuumband eingesetzt, das die Becher aufnimmt (Boden nach oben) und klar vereinzelt zur Inspektionseinheit transportiert. Kamera und Beleuchtung sind eingehaust; das Sichtfenster besteht aus kratzfestem unzerbrechlichem Glas. Jeder einzelne Becher wird nachverfolgt und die Kamera wird automatisch ausgelöst, wenn sich das Prüfobjekt in der optimalen Position befindet. Die Inspektionsparameter sind exakt auf die individuellen Formen und Größen der Becher eingestellt. Wenn Fehler wie Farbspritzer und –flecken, Schmutz, Fremdkörper, Löcher, Risse oder Formabweichungen detektiert werden, gibt das System ein Fehlersignal zur Entfernung des fehlerhaften Bechers aus. Der Reject-Vorgang wird separat überwacht, um ein 100% verlässliches Inspektionsresultat zu garantieren.

TEMA ISI-CUP Leistungsdaten:

- Geeignet für Längen bis zu 140 mm

- Durchsatz 900 Becher/Min.

TEMA ISI-CUP ist:

- Praxiserprobt - zahlreiche Installationen im industriellen Einsatz

- Flexibel - schnelles Umrüsten auf verschiedene Formen und Größen

- Einfach zu bedienen - schnelles Parametrieren neuer Produkttypen

- Präzise - ausgezeichnete Inspektionsleistung und gesonderte Auswurfüberwachung

- Langlebig - hochwertige Hardware

- Zuverlässig - hohe Verfügbarkeit und geringe Wartungskosten

TEMA ISI-CUP bietet:

- 100% objektive Inspektion - Null-Fehler-Konzept

- Support durch ein globales Service Netzwerk

- Beste Anpassung an jede Form und jedes Material

- Benutzerfreundliche Fehleranzeige im Livebild

- Inspektions- und Prozessdaten zur weiteren Verwendung

- Zusätzliches Feature – TEMA STATISTICS GRAPH