RFID / Étiquettes intelligentes

DOWNLOAD

From the very beginning, Mühlbauer machines have been setting global technology standards in terms of speed, quality and flexibility. 1995 we developed the world first RFID inlay production solution and are the major driving force for the RFID production technology. Our mission is to always provide our customers the best price-performance ratio coupled with the certainty of always being at the cutting edge of technology.

Mühlbauer's RFID Competence

Mühlbauer will provide you with an equipment platform that covers all technologies for all your business opportunities - whether you need labels, tickets, tags, cards or ID documents. All of our equipment and the respective processes for antenna production, inlay assembly, converting and personalization fit together perfectly, to form the most efficient RFID production solution. The uniform equipment design furthermore enables easy operation and maintenance and allows the minimization of spare parts stock.

We know the materials, requirements and applications in this area – a unique worldwide competence and equipment portfolio that has grown through 26 years of high volume, high quality RFID production. It is our daily business to plan, install and ramp up complete RFID factories together with our customers – a real partnership that is growing from day one.

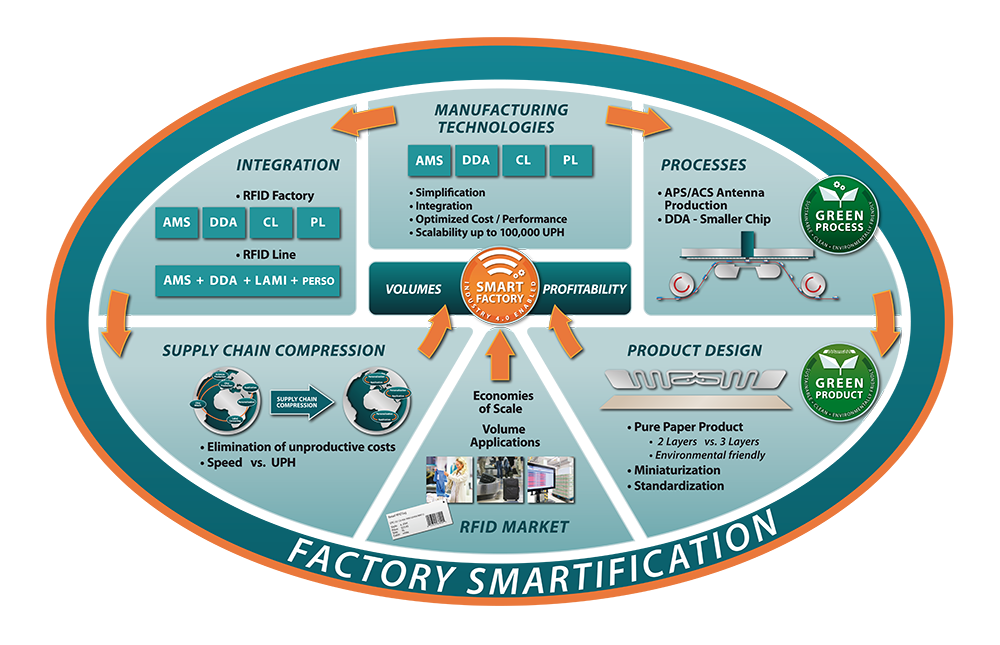

CONCEPT 2023

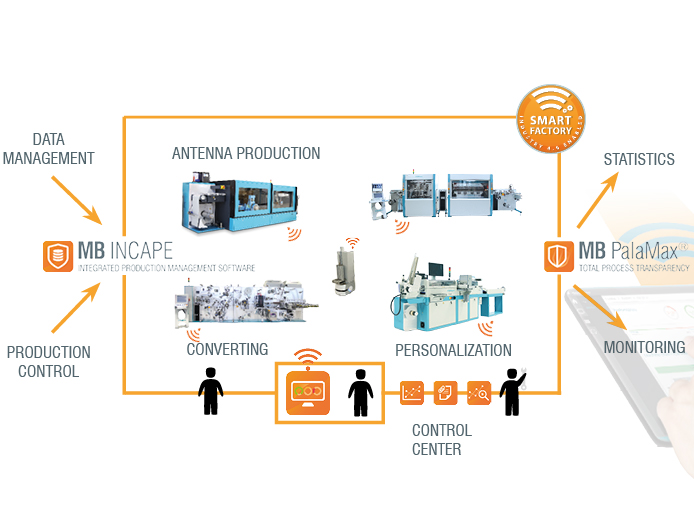

We respect the needs of high volume production linked with a sustainable green process and developed the Concept 2023. It is the roadmap for high automated, sustainable production and material flow. The integration of various manufacturing processes leads to stable and productive manufacturing lines, which guarantee high volume production with consistently high yield and uptimes. With our Concept 2023 we combine the revolutionary advancements with our unmatched expertise to a state-of-the-art technology controlled, monitored by our own-developed software solution.

The RFID Factory

Mühlbauer is able to provide you with the right technology to scope with the demands of tomorrow. Not only supply chain compression, high UPH and yield will be our challenge, in future we need to work on sustainable green manufacturing technologies and the decrease of process costs. Our Concept 2023 will offer the way to build a smart RFID factory Industry 4.0, by having automated control of the manufacturing data; material and process flow. This new factory concept will be able to be more productive on less space and will even further reduce the cost. The total process can be handled by just a few people and guarantee the highest utilization of the installed capacity.